Industrial Paint Tooling

Industrial

Paint Stripping, Tools, and Everything in Between

ISS has been offering comprehensive industrial paint tooling services to our customers for over 25 years. We focus on safe, effective, environmentally friendly solutions that produce excellent results with reliable turnaround times. Over the years, we’ve grown our service offerings to include just about everything our customers need to build and maintain their industrial paint tool systems. Since we design, build, strip, and maintain the tools, ISS can act as your comprehensive rack management solution.

Industrial Paint Stripping

ISS utilizes a thermal stripping process that’s more beneficial for your paint tools, safer for our team, and better for the environment than other paint stripping methods. The entire operation is based on the standard 24-hour turnaround time. That means our customers can reduce their tooling inventories since they know anything they send to ISS will be back in their possession the following day.

We begin by burning paint coatings off steel products with a highly controlled cycle that slowly decomposes the organic material of the coatings. We strictly manage this process to protect the integrity of your tools and provide the long life our customers require. By the end of this step, the coatings are reduced to non-hazardous ash.

Tool Gauging and Repair

A clean paint tool is only useful if it has the integrity to withstand its next job. To help with this, our team performs a complete inspection after cleaning. This can include a physical part check for fit and the function of each load location of the tool.

If we find a missing or damaged component, our team will repair or replace it to ensure 100% density in the first pass of each tool once it returns to your facility.

Tool Design

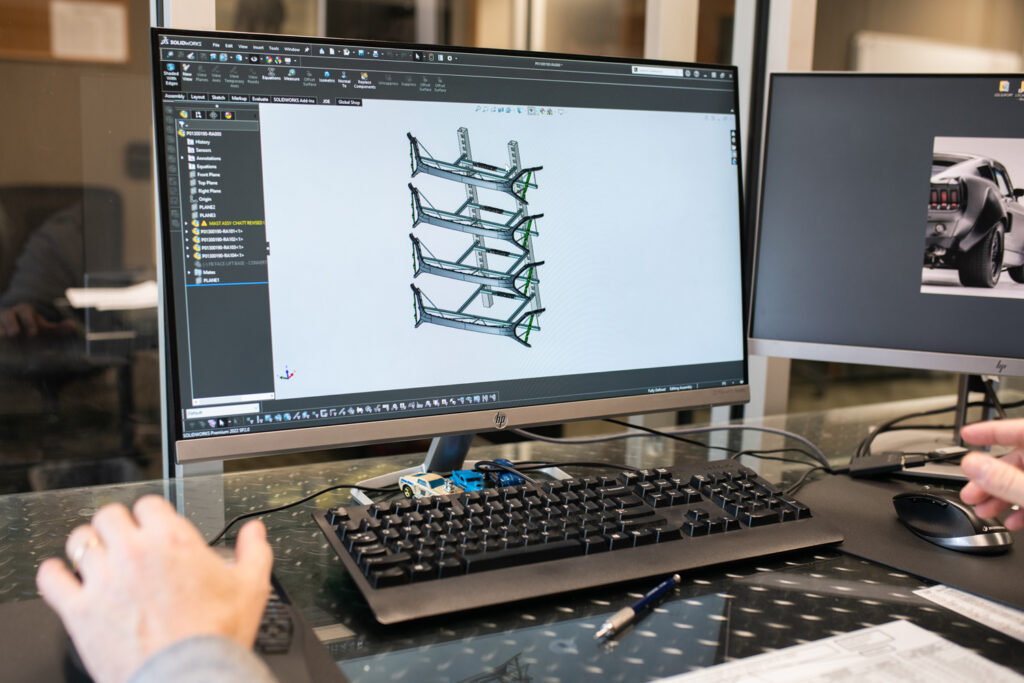

Tool Manufacturing and Modification

Whether you come to us with a design or ask our team to help, we’re happy to manufacture industrial paint tools that work for your parts. If you already have an existing stock of paint tools, we can modify them to better suit evolving needs your organization may be encountering. Then, as with everything we do, we’ll ensure the design fits your needs and performs to your expectations.